Views: 0 Author: Site Editor Publish Time: 2025-06-23 Origin: Site

A diamond core bit helps you drill neat, round holes in hard things like concrete or stone. You use it when you need to drill exactly, even through strong surfaces. More people are buying diamond core bits, especially in mining and building jobs in Asia Pacific and other places. When you use drilling tools, you might also use diamond saw blades for cutting. These tools have industrial diamonds that make drilling quicker and easier, so you can make more holes with less work.

Diamond core bits have industrial diamonds. They drill neat, round holes in hard things like concrete, stone, and brick.There are different diamond core bits for different jobs and ground types. Picking the right bit makes drilling faster and gives better holes.Diamond core bits grind quickly with steady pressure. Water is often used to keep them cool and cut down on dust.Core drilling is common in building, mining, and fixing things. It helps make exact holes and collect samples.Choosing, using, and caring for the right bit makes it last longer. It also keeps people safe and helps drilling work better.

Industrial diamonds are found inside every diamond core drill bit. These diamonds are very hard. This lets them cut through tough things like concrete and granite. Their hardness makes them great for drilling and cutting. People use them in construction and mining. The quality of these diamonds is checked by how well they cut and how fast they wear out. Other things like diamond grain size and cobalt content also matter. Thermal stability is important too. Some bits use Ti-coated diamond particles and cBN. These make the bit stronger and last longer. They help the bit work well under heat and pressure. This means your diamond-tipped drill bit can handle tough jobs and last longer.

Property / Factor | Description / Role |

|---|---|

Hardness | Critical for cutting, drilling, and grinding in construction and mining. |

Quality Assessment | Measured by cutting efficiency and wear rate. |

Cobalt Content | Balances hardness and toughness in the diamond material. |

Diamond Grain Size | Affects abrasion resistance and performance. |

Thermal Stability Enhancements | Ti-coated diamond and cBN improve resistance under high pressure and temperature. |

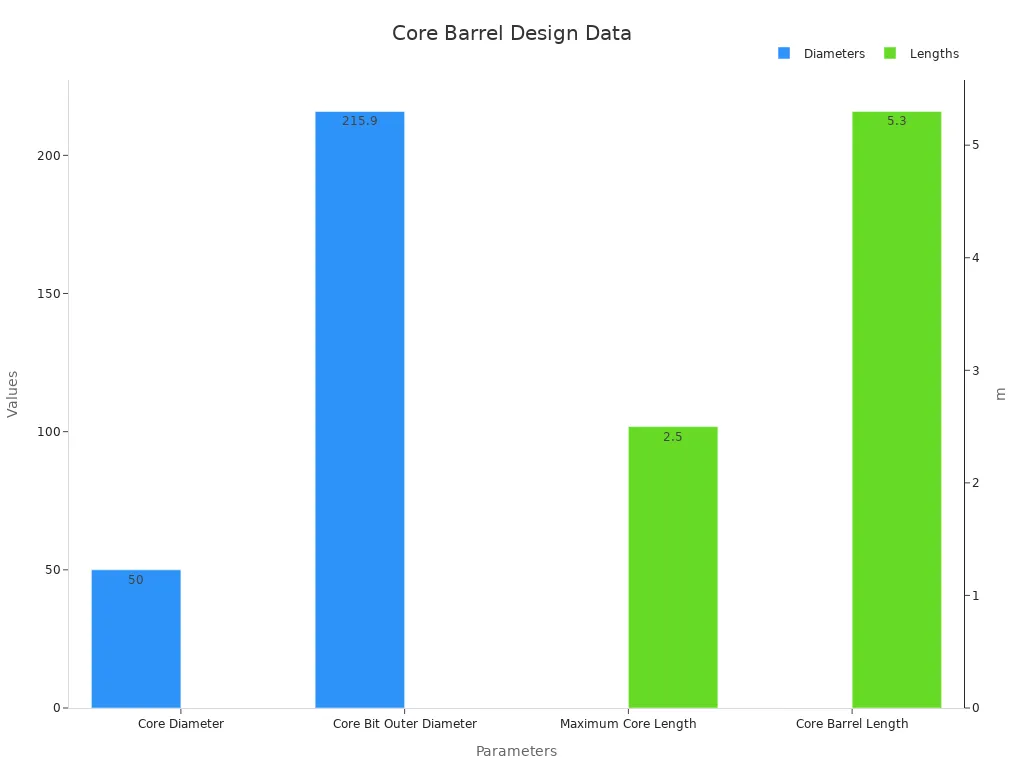

The core barrel gives the drill bit its hollow shape. This shape lets you take out a solid piece, called a core. You use this core for tests or study. Engineers have made the core barrel better. They added things like flapper valves and pressure chambers. These help keep the core safe when drilling is hard. The Improved Pressure Core Sampler uses a wire-line method. It can hold a core up to 2.5 meters long. The flapper valve closes tightly, even with solid bits in the fluid. This design helps you get good samples. It also lowers the chance of losing pressure while drilling.

Parameter | Description/Value |

|---|---|

Sampling Method | Wire-line method |

Core Diameter | 50 mm |

Maximum Core Length | 2.5 m per run |

Pressure Capacity | >30 MPa with pressure loss rate within 2 hours not exceeding 10% |

Core Bit Outer Diameter | 215.9 mm |

Core Barrel Length | 5.3 m |

Huazuan Diamond Tools works on these new designs. Their research helps make drill bits that work well. These bits give good samples, even in hard drilling jobs.

There are different types of diamond core drill bits. Each type is made for certain jobs and materials. The main types are concrete diamond bits and asphalt diamond bits. Concrete bits use a softer metal bond. This helps the diamonds stay sharp as they wear down. Asphalt bits use a harder bond. This keeps the diamonds safe and makes the bit last longer. Some bits have different crown shapes and diamond heights, like the HERO series. These choices help you pick the right bit for the ground and job.

Model | Ground Hardness (Mohs scale) | Diamond Height (mm) | Crown Configuration | Key Performance Metrics and Construction Details |

|---|---|---|---|---|

HERO 3 | 3 to 5.5 (soft, abrasive) | 13 (standard), 16 (Vulcan) | Pie-shape recommended | Excellent penetration/lifespan ratio in soft and abrasive ground |

HERO 5 | 4 to 6 (soft to medium hard) | 13 (standard), 16/20/26 (Vulcan) | N/A | Larger synthetic diamonds for optimal penetration; good in hard ground |

HERO 7 | 5 to 6.5 (medium to hard) | 13 (standard), 16/20/26 (Vulcan) | Various available | Popular matrix; effective on quartz, granite; tailored crown configurations |

HERO 8 | 5.5 to 7 (medium-hard to hard) | 16/20/26 (Vulcan) | N/A | Exceptional penetration rate and durability; tailored for challenging conditions |

HERO 9 | 6 to 7.5 (hard to very hard) | 16/20/26 (Vulcan) | N/A | Matrix allows easy sharpening and long life under demanding conditions |

HERO 11 | 6.5 to 7.5 (very hard to extremely hard) | 16/20/26 (Vulcan) | N/A | Extremely sharp matrix for more bite; designed for basalt, volcanic rock |

HERO 13 | 7 to 8 (very hard) | 16/20/26 (Vulcan) | N/A | Good self-sharpening; freer cutting; maintains sharpness without heavy pressure |

When you pick a core drill bit, think about other tools too. Diamond saw blades and diamond wire saws can help with cutting and drilling. Huazuan sells these tools. Using the right diamond drill bits and diamond-tipped drill bit helps you get clean holes. It also makes your tools last longer and work better.

When you use a diamond core drill, you rely on high-speed rotation to grind through tough materials. The tip of the core drill bit has industrial diamonds. These diamonds are much harder than concrete, stone, or even granite. As you start drilling, the bit spins quickly. This spinning action, combined with steady pressure, lets the diamonds grind away the surface. You do not smash or hammer the material. Instead, you use a grinding motion to make a smooth, round hole.

Scientific studies show that this grinding process works best at higher speeds. When you increase the speed, the drill bit creates more chips and less dust. The friction between the diamonds and the material generates heat. You need to manage this heat to keep the drill bits sharp and working well. Cooling fluids, like water, help reduce the temperature and wash away debris. This keeps the cutting edge clean and prevents damage. The design of the core drill bit also helps control the depth and shape of the hole. You can cut through reinforced concrete, even if it has rebar inside. The diamonds grind both the concrete and the metal, so you get a clean, precise result.

Tip: Always use the right speed and pressure for your core drill. This helps you avoid overheating and extends the life of your diamond drill bits.

After you finish cutting a hole, you need to remove the core. The hollow shape of the core drill bit makes this possible. As you drill, the bit cuts a cylinder out of the material. This cylinder is called the core. You can pull it out and study it, which is important in construction, mining, and geology.

Many tests and case studies show that core extraction works best when you match the drilling speed, pressure, and bit type to the material. For example, using the right core drill bits and adjusting the feed rate can help you recover more of the core. Engineers use special tools and methods to keep the core intact, even in hard or brittle rock. You can use the core to check the quality of concrete or to look for minerals in stone. The efficiency of core extraction depends on both the drill and the operator’s skill.

You get better core recovery when you use the right drilling parameters.

The design of the core drill bit helps protect the core during drilling.

You can improve drilling rates by tuning the speed and pressure.

You can choose between wet and dry core drilling, depending on the job. Wet core drilling uses water to cool the bit and remove debris. This method helps you drill faster and keeps the core drill bit from overheating. Water also reduces dust, making the work area safer and cleaner. Wet drilling works well for cutting tough materials like concrete, granite, and marble.

Dry core drilling does not use water. Instead, you might use air or special lubricants. Dry drilling is useful when water could damage the material or when you work in places where water is not allowed. For example, you might use dry drilling on soft or loose rock. Both methods have their place, but wet drilling usually gives you longer bit life and better core quality.

Method | Cooling Agent | Best For | Benefits |

|---|---|---|---|

Wet Drilling | Water | Concrete, stone, granite | Longer bit life, less dust, cleaner holes |

Dry Drilling | Air/Lubricant | Soft or loose rock | No water needed, good for sensitive sites |

When you pick a method, think about the material, the job site, and the type of core drill you use. You can find more about diamond core drill bits, diamond saw blades, and diamond wire saws at Huazuan’s product page. Using the right tools and methods helps you get the best results when drilling holes or cutting a hole in tough materials.

You can use a core drill on many hard materials. Core drilling works best on concrete, stone, brick, granite, marble, and tiles. These materials are common in building and fixing projects. Using a diamond core drill gives you smooth holes in tough surfaces. Concrete is drilled the most, but you can also drill reinforced concrete and rough stone. Tiles need extra care, but diamond core drills make it easier and cleaner to drill them.

Tests show that diamond core drills work well on hard and brittle things. For example, when drilling ceramics or composites, you get neat holes with less damage. Rotary ultrasonic machining with diamond core drills lowers the force needed. This helps keep the holes tidy. You can also use these tools on rocks like serpentinized peridotite. You get fast drilling and good core samples.

Tip: Always pick the right core drill for your material. This helps you get the best results and keeps your tools working well.

Core drilling is used in many jobs. In construction, people drill holes for pipes, cables, and anchor bolts. You can use a concrete core drill to make spaces for HVAC or fire safety gear. In mining, core drilling helps collect rock samples. Masonry workers use core drills to cut brick and stone for repairs or utilities. Tiles often need exact holes for plumbing or wires, and diamond core drills make this easy.

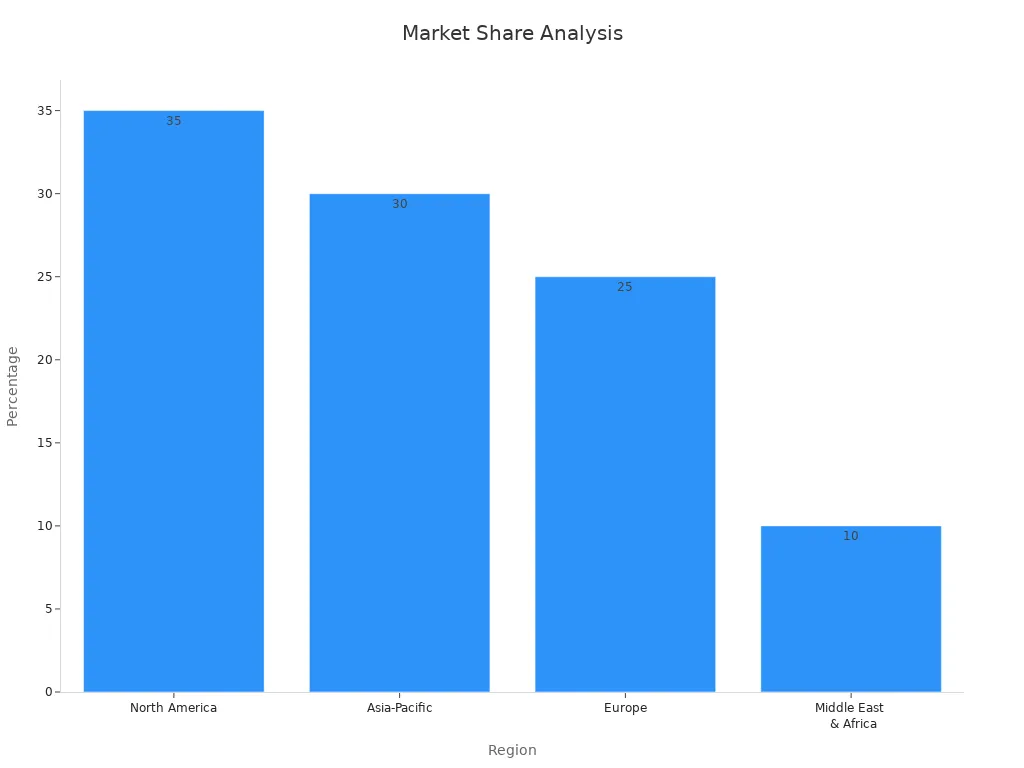

The market for core drilling is getting bigger. In 2024, the world market was USD 907.2 million. By 2033, it may go over USD 1.3 billion. This growth comes from more building and mining work. North America is the biggest market, but Asia-Pacific and Europe are also growing.

You can see core drilling in many places: - Construction sites for holes in concrete and tiles - Mining fields for taking core samples - Renovation jobs for new pipes or wires - Masonry work for openings in brick or stone

Diamond core drills give you neat holes and make little noise. You get clean holes without cracks or lots of dust. This is good for careful jobs near finished areas. You can also use other diamond tools, like diamond saw blades and diamond wire saws, for cutting and shaping.

Industry | Typical Application |

|---|---|

Construction | Drilling holes in concrete, tiles, stone |

Mining | Core sampling in rock and minerals |

Masonry | Openings in brick, granite, and marble |

Renovation | Utility installation, ventilation holes |

Core drilling tools help you finish jobs faster and better. You save time, do less work, and keep your area clean. When you pick the right core drill, you make drilling safer and easier.

You get very precise holes when you use a diamond core drill. The sharp industrial diamonds at the tip grind through hard surfaces without breaking the edges. This means you can drill clean, round holes in concrete, granite, or marble. You do not need to worry about cracks or rough edges. Many builders and engineers choose diamond core drill bits for jobs that need accuracy, such as installing pipes or cables. If you want to make neat holes in tiles or stone, these tools help you finish the job with less effort. You can also use related tools like diamond saw blades for cutting straight lines or shapes.

Diamond core drill bits last much longer than regular drill bits. The diamonds are very hard, so they do not wear out quickly. You can drill many holes before you need a new bit. This saves you time and money. The design of the bit also helps you drill faster. You spend less time changing tools and more time working. Many professionals use diamond core drill bits for big projects because they are reliable and efficient. If you need to cut through tough materials, these bits keep working even under heavy use.

You will notice less dust and noise when you use a diamond core drill. The grinding action creates fewer airborne particles, which keeps your workspace cleaner. Research shows that diamond-coated drill bits make less noise than other types, such as tungsten carbide. Harder drill bits, like those with diamond coatings, lower the noise level during drilling. This makes your work area safer and more comfortable. Studies also show that the type of rock and the hardness of the bit affect noise levels. Diamond core drills help you work quietly, even on tough jobs. These advantages of diamond core drill bits improve your working environment and help you meet safety standards.

Diamond-coated bits produce less noise than other coatings.

Harder bits and better design mean less dust and a cleaner workspace.

You get a safer and more pleasant drilling experience.

When you start core drilling, choosing the right diamond drill bit is important. You want a bit that matches your material and your project needs. Experts from Boreholeflow.com suggest looking at drill performance, torque, and how the bit fits your core drill. You should check if your drill has the right chuck system and clutch settings. These features help you control the drilling process and keep your work safe.

You can use a simple checklist to help you pick the best core drill bit:

Material Type: Know if you are drilling concrete, brick, granite, or marble.

Bit Size: Pick a size that matches the hole you need.

Drill Compatibility: Make sure your bit fits your core drill and works with your drilling tools.

Project Needs: Think about how deep and wide your hole should be.

Cooling Method: Decide if you need wet or dry core drilling.

Tip: Use downloadable drill comparison charts from expert guides to match your core drill bit to your project. This helps you get the best results with your core drilling tools.

You can also explore related products like diamond saw blades and diamond wire saws for cutting and shaping tasks. These tools work well with your core drilling projects.

Proper use and care of your core drill bit help you drill more holes and save money. Research from drilling companies shows that regular checks and cleaning make your bits last longer. You should always inspect your bit for cracks or wear before you start drilling. Clean your bit after each use to remove dust and debris.

Replace worn or damaged bits to avoid poor drilling results.

Use the right speed and pressure to prevent overheating.

Store your core drill bits in a dry place to stop rust.

Follow the manufacturer’s instructions for your drilling tools.

Performance reports from major companies show that new bit designs and good maintenance can double the life of your core drill bit. You can also use computer models and lab tests to learn the best ways to use your core drill. If you rent or repair bits, learn about wear patterns and how to refurbish them.

Note: Good maintenance keeps your core drilling safe and efficient. It also helps you get clean, round holes every time.

You now know how a diamond core bit helps you with drilling in hard materials. This tool gives you clean, round holes and makes drilling faster and safer. You can use it for drilling concrete, stone, or brick. Many people also use diamond saw blades and diamond wire saws for cutting and shaping. When you choose the right tools, you make drilling easier and get better results. Visit Huazuan’s site to find more diamond tools for your next drilling project.

You can drill concrete, stone, brick, granite, marble, and tiles. Diamond core drill bits work best on hard surfaces. You get clean, round holes with less effort. For more options, check out diamond saw blades and diamond wire saws.

Start by knowing your material and hole size. Match the bit to your drill. Use a wet or dry bit as needed. Visit Huazuan’s diamond tools page for more help on how to choose a diamond core bit.

Yes, you can use a diamond core bit for reinforced concrete. The industrial diamonds grind through both concrete and rebar. You get smooth holes without damaging the bit. Always use water to cool the bit and remove debris.

Inspect your bit before each use.

Clean it after drilling.

Store it in a dry place.

Replace worn bits quickly.

Good care helps your diamond core drill bit last longer and work better.

No.351, Dingshi Jing, Shijing, Dongling Town, Huian, Quanzhou, Fujian, China

No.351, Dingshi Jing, Shijing, Dongling Town, Huian, Quanzhou, Fujian, China

+86-595-86780371

+86-15905012435

Copyright © 2024 Huazuan Diamond Tools Co., Ltd. All rights reserved. Sitemap Privacy Policy 闽ICP备2024071061号-1