Views: 0 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

A diamond segment is the part that cuts in diamond tools. It gives the tool its hardness and sharpness. This helps remove material quickly and well. Each segment has a working layer and a transition layer. Both layers are important for how the tool works. These segments help cutting and grinding tools work on hard materials. They make the tools fast and accurate. The table below shows different segment types and what they do:

Segment Type | Structure Description | Main Functions and Characteristics |

|---|---|---|

Multi-layer Diamond Segment | Working and transition layers are stacked in steps | Cuts fast, costs less, and works more |

Sandwich Diamond Segment | Has three thick working layers with different diamond amounts | Lasts longer, makes smooth lines, good for marble |

Arix Diamond Segment | Diamonds are set in order in the working layers | Cuts the same every time, works better |

Diamond abrasive blades and core bits need these segments. They help the tools last longer and handle heat. Huazuan Diamond Tools makes high-quality diamond tools. They also make polishing and shaping tools. Professionals all over the world trust them for good tools.

Diamond segments are the parts of tools that cut. They hold diamond grains in a metal bond. These segments cut hard things like stone and concrete. The segment has two layers. The working layer has diamonds for cutting. The transition layer keeps the segment strong. It also helps the segment stay attached to the tool. Picking the right diamond segment shape, size, and bond hardness is important. This helps the tool cut faster and more accurately. It also makes the tool last longer. Diamond segments can self-sharpen. The metal bond wears away and shows new diamonds. This keeps the tool sharp and working well for a long time. Good diamond segments, like those from Huazuan Diamond Tools, help tools cut better. They also make tools last longer and work safely in many jobs.

A diamond segment is a special part on the edge of a blade or core bit. It holds diamond grains inside a metal bond. These grains give the segment its cutting power. The segment connects to the tool and does the main cutting and grinding work.

Diamond segments come in many shapes and sizes. Some shapes are M-shaped, K-shaped, fan-shaped, and sandwich. M-shaped segments have high sides and a low middle. This helps the blade cut faster and last longer. Sandwich segments have layers that help cut better and stop chipping. Most segments are about 40mm long and 10mm wide. The size can change depending on the tool and material.

A diamond segment has working and non-working layers. The working layer has diamond grains and does the cutting. Non-working layers help cool the segment and remove chips. This design makes the tool cheaper and work better. The inside structure, shape, and bond all affect how well it cuts.

Note: Pick the right segment shape and size for the material. Softer stones like marble need a softer bond and bigger diamonds. Hard granite needs a harder bond and smaller diamonds.

Characteristic | Description & Impact |

|---|---|

Diamond grains | Big grains cut fast but wear out quickly. Small grains last longer but cut slower. Size 50/60 works best. |

Diamond concentration | More diamonds make the tool last longer but cut slower. Fewer diamonds with big grains cut faster. |

Diamond strength | Best strength is 130-140N. Too strong makes it less sharp. Too weak makes it break. |

Bonding materials | Metal powders like Fe-Ni-Cu-W make it strong. Copper bonds are good for soft stones. Tungsten carbide makes it harder. |

Sintering process | Heat and time make the bond strong. |

Layered segments | Working and non-working layers help cool, lower cost, and make it sharper. |

Diamond segments do many important jobs in cutting and grinding tools. Their main job is to cut hard things like granite, marble, concrete, and masonry. The diamond grains act like tiny cutting points. When the blade spins, these grains grind away the material. This makes a clean and neat cut.

The segment’s design also helps cool the blade and remove dust. Gaps between segments let air flow and dust escape. This keeps the blade cool and stops it from getting too hot. The metal bond holds the diamond grains in place. This keeps them sharp and working well.

Diamond segments help tools work better and last longer. Good segments, like those from Huazuan Diamond Tools, use strong materials and smart bonding. This makes blades last longer and need fewer changes. Workers can switch tools fast and keep projects moving.

Main jobs of diamond segments:

Cut stone and concrete quickly and well.

Make clean cuts with little chipping.

Help grind and shape stone.

Keep the tool cool and remove dust for safety.

Make tools last longer and cost less to fix.

Diamond segments can be used in many tools. They work in blades, core bits, and polishing tools. Their design lets them be used in many jobs, like building and stone work. Picking the right segment helps people get better results and work faster.

Tip: Always pick a diamond segment that fits the material and tool. This gives the best speed, accuracy, and tool life.

The working layer is the most important part of diamond segments. It holds diamond particles in a metal powder mix. The diamonds do the cutting and grinding work. They come in many shapes and sizes. This changes how well the segment works. Granular diamonds are good for cutting and drilling. Flat diamonds are better for grinding and polishing.

The metal mix uses iron, copper, nickel, and cobalt. Each metal helps in a different way. Iron makes it cheaper. Copper helps the mix stick together. Nickel makes it tougher. Cobalt lets it handle high heat. The metal mix wears away as you use the tool. When it does, new diamonds show up. This keeps the segment sharp.

How thick the working layer is and how many layers it has changes how it cuts. The table below shows how these things change how the segment works:

Working Layer Thickness & Number of Layers | Cutting Efficiency | Segment Life | Sharpness | Suitable Stone Types | Cost & Production Notes |

|---|---|---|---|---|---|

Narrow width, fewer layers | Slightly better | Lasts longer | Medium | Softer stones (like marble) | Costs a bit more, sandwich design |

Wide width, fewer layers | Not as good | Wears out fast | Medium | Soft and breakable stones (like volcanic rock, soft marble, granite) | Cheaper, simple design |

Narrow width, more layers | Cuts sharper | Does not last longer | Better | Soft to medium-hard stones (abrasive marble, granite) | Cheaper, can be used for many jobs |

Wide width, more layers | Cuts very sharp | Wears out faster | Very sharp | Hard, very hard, and rough stones | Costs more to make, takes more work |

Tip: Picking the right working layer design helps diamond segments cut faster and last longer. This is important when cutting different kinds of stone.

The transition layer is between the working layer and the steel blade. It helps keep the diamond segment attached when cutting or grinding. It acts like a bridge. It matches the working layer and the steel blade.

The transition layer has some important jobs:

It is strong and tough so the segment does not break off.

It welds well to the steel blade for strong laser welding.

It expands at almost the same rate as the working layer so it does not crack.

It sticks well to both the working layer and the steel blade.

Makers use metals like cobalt, nickel, iron, and chromium in this layer. Sometimes, they add ceramic powders like aluminum oxide or silicon carbide. These help the layer stick better, be tougher, and last longer. The chart below shows what metals and ceramics are used and how much of each:

This careful design helps diamond segments from Huazuan Diamond Tools work well in saw blades, core bits, and diamond wire saws. The transition layer lowers stress and helps the tool last longer. This makes it a good choice for workers who need tools they can trust for cutting and grinding.

Diamond grains are the most important part of a diamond segment. These grains do the cutting in tools like diamond saw blades and core bits. Most companies use synthetic diamond grains because they work the same every time. In metal-bonded diamond tools, the grains are mixed into a metal base. The grains are usually between 420 and 590 micrometers wide. This size is good for cutting in factories.

How many diamond grains there are and how big they are matters a lot. More grains mean each one does less work. This makes the segment last longer. Bigger grains cut faster but wear out quicker. Smaller grains make smoother cuts and last longer. Changing the size and number of grains helps match the tool to the job. This makes the tool faster and stronger.

Diamond impregnated segments need the right mix of grains. The best mix lets the tool cut hard things like granite or concrete. It also keeps the tool sharp and working well.

Tip: Pick the right diamond grain size and amount for your job. This helps you get the best results.

The metal bond keeps the diamond grains in place. It also controls how the grains show during cutting. Common metal bonds are made from iron, copper, cobalt, or silicon carbide. They also have small amounts of nickel, aluminum, chromium, and titanium. Each bond type has different strengths, like being hard or handling heat.

The metal bond changes how long the segment lasts and how well it works. Harder bonds hold the grains longer. This makes the tool last longer but can slow cutting. Softer bonds let the grains come out faster. This helps cut hard things quickly but the tool may not last as long. You need to match the bond to what you are cutting. A soft bond is good for hard concrete. A hard bond is better for softer things like asphalt.

Main things about metal bonds:

Chemical holding power keeps the diamonds in place.

Physical holding power depends on how hard and stretchy the bond is.

Wear resistance means the bond and diamonds wear out together.

Thermal stability lets the segment handle high heat.

Companies like Huazuan Diamond Tools use special bonding methods. This helps their tools work well and last a long time. Their diamond saw blades and wire saws are better because of these strong metal bonds.

Manufacturers make diamond segments using a careful process. First, they mix diamond powder and metal powder in exact amounts. They add other things to help the segment work better. Workers put this mix into a mold and press it into shape. They use cold pressing at room temperature or hot pressing with heat. This makes the segment strong.

The sintering process has three main steps:

At first, atoms move and form necks between particles. Gases and forming agents leave the mix.

Next, the necks get bigger. Pores get smaller, grains grow, and the segment gets stronger.

Last, most pores close and turn round. The segment shrinks and gets even denser, but some pores may stay.

It is important to control heat and pressure very carefully. Good vacuum sintering machines use smart controllers and sensors. These keep the process steady. The machines can follow up to 256 preset sintering curves. They change heat and pressure as needed. This careful control helps stop mistakes and makes sure each diamond segment is good.

After sintering, workers check the segments. They use calipers to measure the size. Each one must match the design within 0.1mm. They also check weight and density at different times. The right mix and high density help the segment last longer and work better in tools.

When the diamond segments are ready, workers attach them to tools. These tools include diamond saw blades and diamond core bits. There are two main ways to do this:

Brazing: Workers put silver solder between the segment and steel core. They heat it until the solder melts and sticks the segment to the core. This works well for wet cutting but not for high heat from dry cutting.

Laser Welding: A laser melts part of the segment and steel core. This joins them together very strongly. Laser-welded tools can handle high heat and last longer in hard jobs.

Both ways make sure the diamond segment stays on the tool. Huazuan Diamond Tools uses advanced welding to make strong products. Their diamond wire saws and polishing tools also use these careful steps.

Tip: Pick a tool with well-attached diamond segments. This makes it safer, faster, and helps the tool last longer.

Diamond segments use tiny diamond pieces in a metal bond to cut hard things. When the blade spins, the diamonds scratch and grind the surface. This works on stone, concrete, and other tough stuff. The cutting happens because of rubbing and hitting. The diamond pieces push into the material and make small cracks and chips. As the blade moves, these chips break off and take away some material.

The metal bond, called the matrix, is also important. It slowly wears down as you cut. This lets new diamond pieces show up and keeps the blade sharp. Cutting causes different kinds of wear, like rubbing, hitting, and heat damage. These can break the diamond pieces and make new sharp edges. This keeps happening as the blade works, so it keeps cutting well.

Things like diamond size, shape, and how they are spread out change how the blade cuts. The bond’s strength and how fast the blade spins also matter. Tools like diamond saw blades and diamond wire saws use this way to cut very hard things. How well the diamond segment works depends on all these parts working together.

Tip: Pick the right diamond blade for what you are cutting. This helps you cut faster and makes your tool last longer.

Self-sharpening is a special thing that diamond segments can do. It helps the tool stay sharp and work well for a long time. As the blade cuts, the metal bond wears away just right. This lets new diamond pieces come out before the old ones get dull. This stops the blade from getting smooth and losing its cutting power.

Some diamond segments have special coatings or materials. These make tiny holes when grinding. The holes help get rid of chips and heat. This keeps the blade cool and clean. This design keeps the rubbing even and makes the cuts better. Self-sharpening means you do not have to stop often to fix the tool.

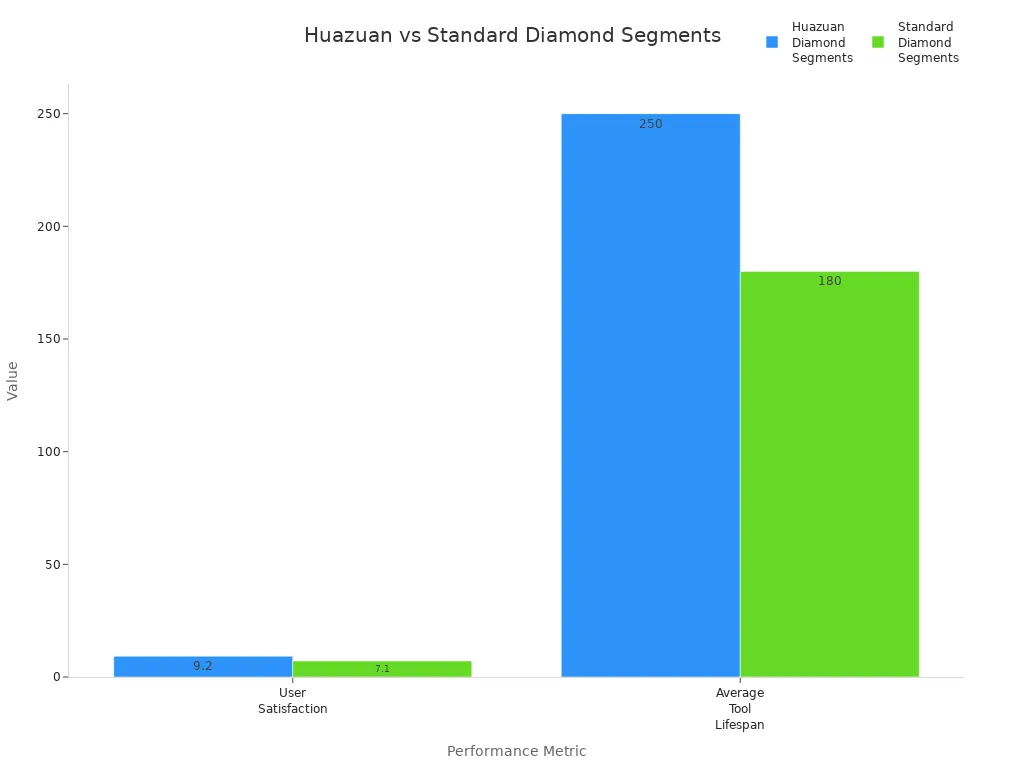

Tests show self-sharpening diamond tools can grind up to 30% better. They also make surfaces smoother by more than 25%. This gives you smooth, damage-free surfaces and makes the tool last longer. Huazuan Diamond Tools uses smart technology to make diamond segments that self-sharpen well. Their diamond saw blades and core bits give good results for workers everywhere.

Note: Self-sharpening diamond segments help you save time and money. You do not have to change blades as often.

Diamond segments are very important in cutting and grinding. They work on some of the hardest materials in factories. Workers use diamond saw blades and other diamond tools for many jobs:

Natural stone like granite and marble is cut in quarries and for building.

Concrete and asphalt are cut for roads and polished for floors.

Semiconductor materials, such as silicon, need careful cutting for chips and wafers.

Ceramics and glass need diamond grinding tools to make them smooth.

Fireproof materials are shaped and cut with strong diamond blades.

These tough materials need diamond tools because they are hard and last a long time. Huazuan Diamond Tools makes many kinds of diamond saw blades, abrasive blades, core drill bits, and grinding cup wheels. Their tools help people get clean cuts and use their tools longer.

Different jobs need special segment designs for the best results. The design of a diamond blade changes with the material and job. The table below shows how segment features fit different uses:

Material Type | Segment Bond Hardness | Diamond Grit Size | Segment Shape/Technology | Typical Tool Example |

|---|---|---|---|---|

Concrete (including reinforced) | Tougher bond | Larger grit | Advanced tech like Arix | Diamond saw blade, diamond core drill bit |

Granite/Natural Stone | Medium bond | Medium grit | Balanced for precision | Diamond circular saw blades |

Asphalt/Green Concrete | Softer bond | Smaller grit | Wedge or drop segments | Diamond circular saw blades |

Concrete blades have a tougher bond to cut through steel bars. Granite blades use a medium bond for good, even cutting. Asphalt blades use a softer bond and smaller grit for quick, smooth cuts. Huazuan Diamond Tools uses new segment technology to make blades faster and stronger. Their diamond blades and grinding cup wheels work well for many industries.

Note: Picking the right diamond blade and segment design saves time and money. It also makes tools safer and last longer.

Huazuan Diamond Tools is known around the world for good quality and new ideas. Their diamond saw blades, abrasive blades, and core drill bits help with stone cutting, building, and factory jobs everywhere.

Diamond segments give cutting tools their strength and sharpness. Each segment has a working and transition layer that helps cut hard materials like granite and concrete. Choosing the right segment depends on material type, bond hardness, and blade design. High-quality segments from Huazuan Diamond Tools offer smooth cuts, long life, and less vibration.

To get the best results and keep tools safe, users should:

Use the correct segment for each job.

Keep blades cool with water.

Clean and store blades properly.

Huazuan’s diamond saw blades, core bits, and wire saws help users work faster, safer, and with less waste.

A diamond segment helps cut or grind hard things. It works on stone, concrete, and ceramics. The segment has diamond grains that cut tough surfaces. This makes tools like diamond saw blades work better. It also helps core bits last longer and cut faster.

You need to match the segment to what you are cutting. For granite or marble, pick a segment with the right bond and diamond size. Huazuan Diamond Tools gives advice and has many segment choices. They help you find the best one for your job.

Yes, diamond segments fit many kinds of tools. They go on diamond saw blades, core bits, and wire saws. Each tool uses a segment made for its own job. This helps the tool cut or grind the right way.

The metal bond wears away as you use the tool. This lets new diamond grains show up. The segment stays sharp and ready to cut more. This self-sharpening saves time for users.

Huazuan Diamond Tools uses new technology and checks quality closely. Their diamond segments and other tools work well and last a long time. People all over the world trust their products for good results.

No.351, Dingshi Jing, Shijing, Dongling Town, Huian, Quanzhou, Fujian, China

No.351, Dingshi Jing, Shijing, Dongling Town, Huian, Quanzhou, Fujian, China

+86-595-86780371

+86-15905012435

Copyright © 2024 Huazuan Diamond Tools Co., Ltd. All rights reserved. Sitemap Privacy Policy 闽ICP备2024071061号-1